Perfect Motor Anti Condensation Heater Wiring Diagram

Products for this application.

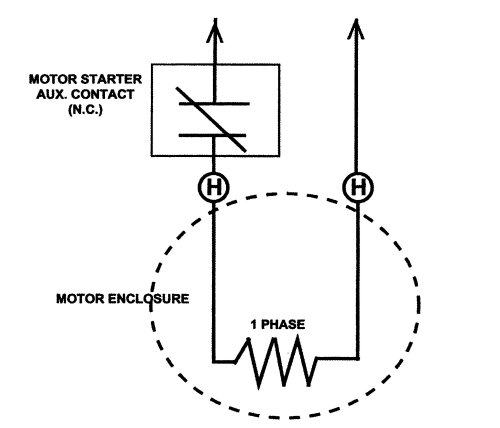

Motor anti condensation heater wiring diagram. Specifying anti condensation heaters at the design stage can save the expense of costly rewinds and down time. Kp 1000 1x thermal winding protection. For example a heater and its installation in a typical 60 hp 364t frame motor will cost approximately 210.

Three phase motors with slipring rotor. Products for this application. Additional connection diagram for.

The special glass fibre heating. Typical applications include electric motors generators and alternators which operate in damp or wet conditions e g. The oem or the rewinder fits the selected ach heating tape to the end turns of the motor stator pack by lacing or by use of suitable adhesive insulating tape applied longitudinally over the.

The safety risk is enormous and the cost of. Kp 1700 1x anti condensation heating. The wiring diagrams of the different configurations foreseen are given on the drawing of picture n 6.

They are not to be. The installation of flexible resistance heating strips or coils is by far the simplest and least expensive method. Prevent short circuit risks caused by condensation during cooling after using electric motors and occurring when restarting them.

These strip space heaters. For 3 phase ac motors operating in damp conditions the best way to prevent condensation is to install resistance heaters inside the motor. These anti condensation heaters are rated 65 w 220 v.